The Future of Foam Processing is Here

Foam processing has become a specialized industry requiring precision, efficiency, and adaptability. Industries such as packaging, signage, automotive, and aerospace depend on foam for protective packaging, insulation, and structural components.

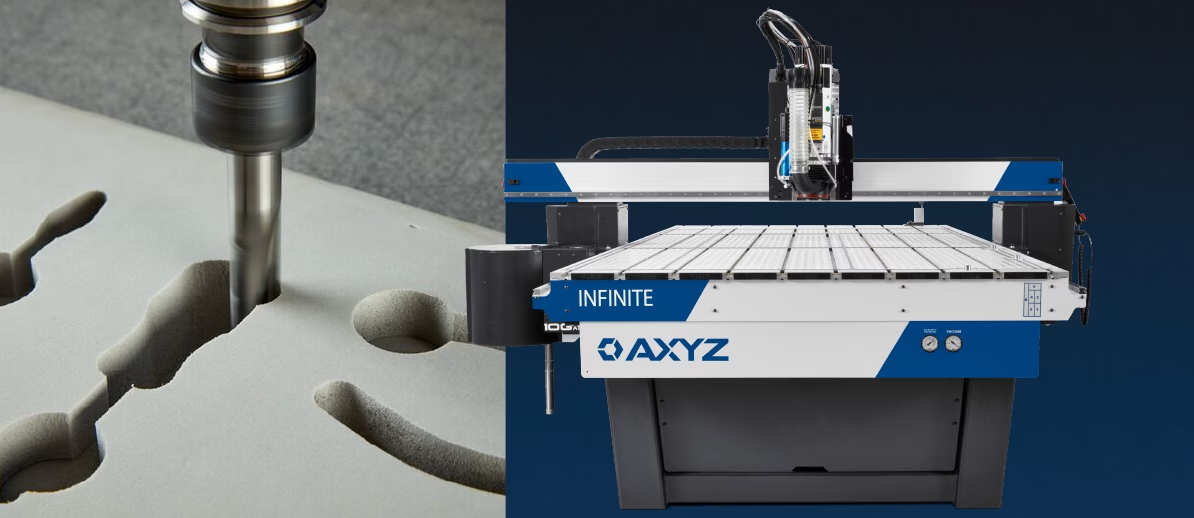

At AXYZ, we specialize in high-performance CNC routers designed for precise foam processing. Our Infinite and Trident CNC routers offer hybrid cutting solutions, combining spindle cutting with oscillating and tangential knives, making them ideal for processing foams of various densities and compositions.

While WARDJet CNC waterjets provide an alternative for high-speed, through-cut applications, AXYZ CNC routers excel in intricate detailing, pocketing, chamfering, and multi-material processing, making them the preferred choice for many foam fabricators.

Understanding Foam and Its Growing Market

Foam materials are essential across industries due to their lightweight, durable, and protective properties. The global polymer foam market is expected to grow at a 7.73% CAGR from 2023-2030, with increasing demand in packaging, construction, furniture, and automotive applications.

Selecting the right foam type is critical, as visually similar foams can have vastly different density, firmness (ILD/IFD), and structural integrity. AXYZ CNC routers provide precise, repeatable cuts that maximize material efficiency and minimize waste.

Why Choose AXYZ CNC Routers for Foam Processing?

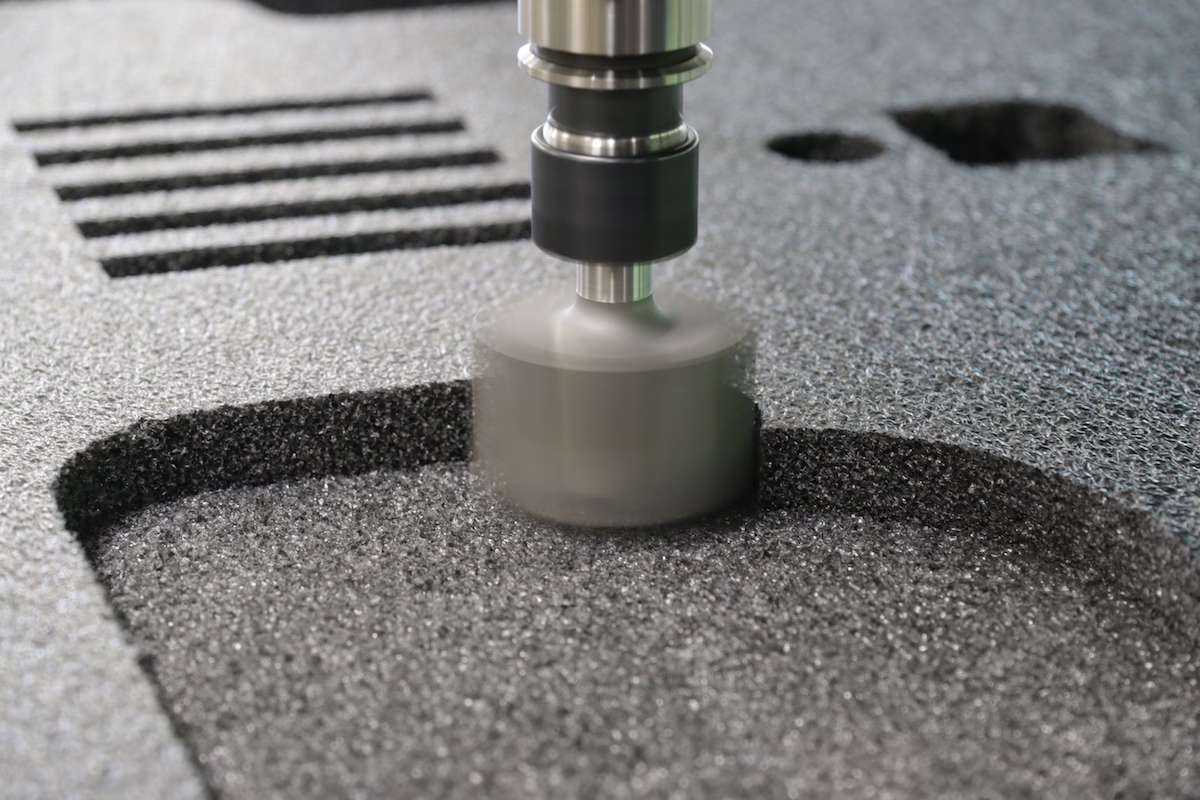

For foam processing applications requiring precision, versatility, and efficiency, AXYZ CNC routers provide a powerful solution. Our hybrid cutting technology combines spindle cutting with oscillating and tangential knives for clean, accurate cuts on a wide range of foam materials.

Key Advantages of AXYZ CNC Routers in Foam Processing

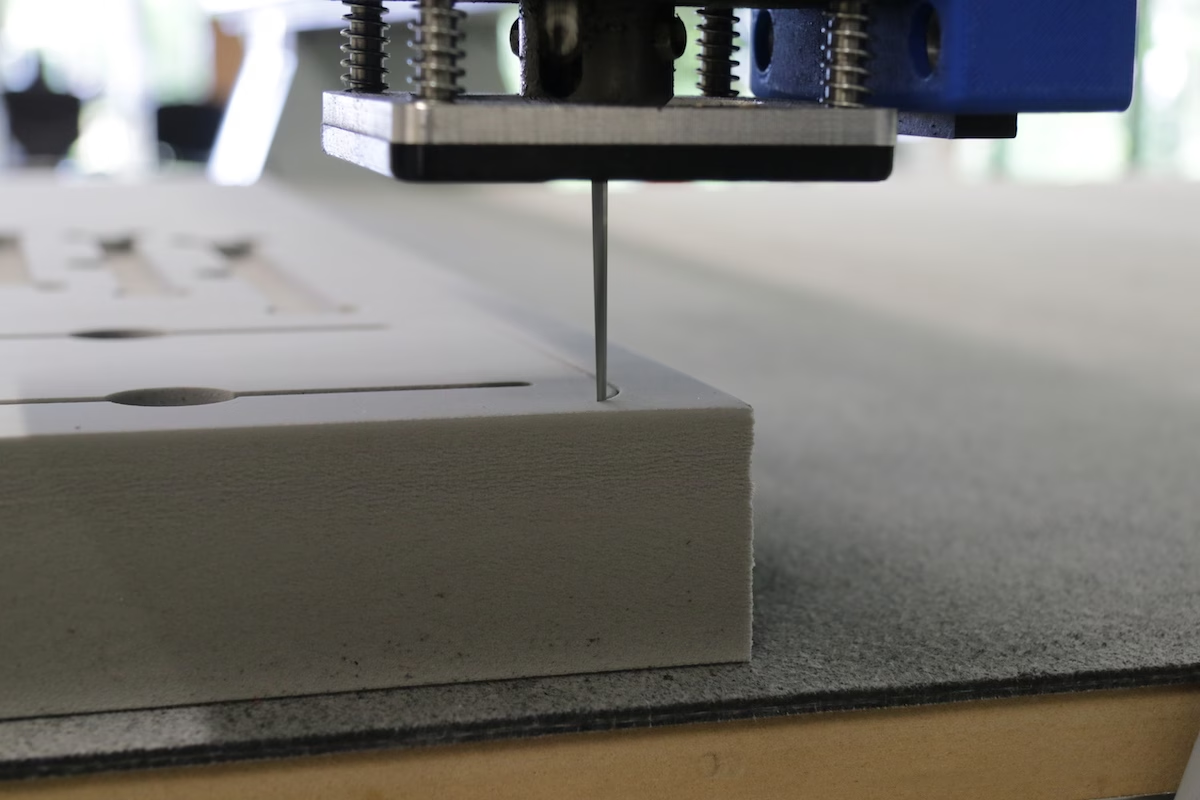

- Hybrid Cutting Capabilities – AXYZ routers integrate spindle cutting with oscillating and tangential knives for precise foam processing.

- Customizable Gantry Clearance – Standard clearance of 12”, with options up to 24”, accommodates thick foam sheets.

- High-Speed Production – Achieve consistent, repeatable results with efficient processing speeds.

- Optimized for Multi-Material Applications – Cut Polyethylene (PE), Crosslink Polyethylene (XLPE), Polyurethane (PU), and more.

- Advanced Automation – Automatic tool changers, laser alignment and various cutting devices improve efficiency and reduce downtime.

Applications

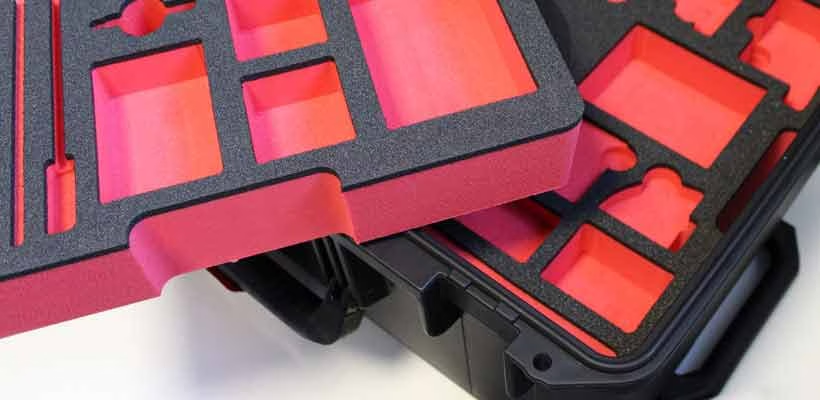

- Protective Packaging – Custom foam case inserts, tool organizers, and impact-resistant packaging.

- Signage & Displays – 3D lettering, point-of-purchase displays, and exhibition stand components.

- Marine & Automotive – EVA foam processing for boat decking, automotive interiors, and protective padding.

Foam Cutting Technologies: AXYZ CNC Routers vs. WARDJet Waterjets

While WARDJet CNC waterjets provide high-speed through-cuts and stack cutting capabilities, AXYZ CNC routers are the preferred choice for applications requiring intricate detailing, pocketing, chamfering, and material-specific adjustments.

| Feature | AXYZ CNC Routers | WARDJet CNC Waterjets |

| Material Thickness | Up to 12”+ | Up to 12”+ |

| Cutting Speed | High Up to 500 IPM | Very High (Up to 1000 IPM) |

| Best for | Intricate designs, pocketing, chamfering | Through cuts, high-speed bulk processing |

| Material Compatibility | PE, XLPE, PU, EPP, EPS | PE, XLPE, PU, EPP, EPS |

| Heat-Affected Zone (HAZ) | Minimal | None |

| Tool Wear | Moderate | None |

| Stack Cutting | No | Yes |

For applications that require precision detailing and multi-functional (or multi-dimensional) processing, AXYZ CNC routers provide superior versatility and efficiency.

Customer Success Story: GWP Protective Expands Production with AXYZ

Background

GWP Protective, a leading manufacturer of custom foam inserts and protective packaging, needed to expand its production capacity and improve efficiency while maintaining high precision and consistency.

The Challenge

- The company required a machine capable of handling high production volumes.

- Edge quality and cutting precision were critical for their custom protective foam solutions.

- A reliable, user-friendly CNC solution was necessary to ensure consistent output and ease of training for operators.

The AXYZ Solution

GWP Protective invested in an AXYZ Infinite 4010 CNC Router, equipped with:

- Pneumatic Oscillating Knife – For precise foam cutting.

- 10HP HSD Spindle – For enhanced processing power.

- Single Vacuum Blower System – For optimal material hold-down.

The Results

- Increased Cutting Speeds – Improved efficiency and reduced production time.

- Superior Edge Quality – High-quality finished cuts with minimal material waste.

- Greater Production Efficiency – The AXYZ router enabled GWP Protective to scale production while maintaining consistency.

Read more about GWP Protective’s investment in AXYZ CNC technology:

GWP Protective’s CNC Investment Story

Why AXYZ? Your Partner in Foam Processing Excellence

At AXYZ, we provide cutting solutions that optimize workflow, increase efficiency, and maximize ROI.

- Decades of Experience – Over 30 years of expertise in CNC manufacturing.

- Tailored Configurations – Machines designed for specific foam processing applications.

- Industry-Leading Support – Application specialists, 24/7 technical assistance, and custom training programs.

Ready to optimize your foam processing? Contact us today to find the perfect AXYZ CNC Router for your business.

Visit AXYZ.com to Learn More!