Neglecting the maintenance of collets, tools and your machine dramatically reduces the performance of all three critical components. By following all the steps in this blog post, you’ll be well on your way to maintaining peak performance.

Category: CNC Routers

1

For companies that invest in CNC router equipment to manufacture cabinets, furniture components, countertops and other wood, metal and plastic products, initial and ongoing training is essential. To be effective, training begins at a basic level with how to setup the router table correctly.

When shopping for a CNC router, it’s easy to think that price is the most important factor. While sticking to a budget is important, it is not the only consideration in the decision-making process. There may be some critical differences between the lower and higher priced CNC routers and, because of these differences, the lower-priced machines can end up costing more in the long run than the higher-priced models.

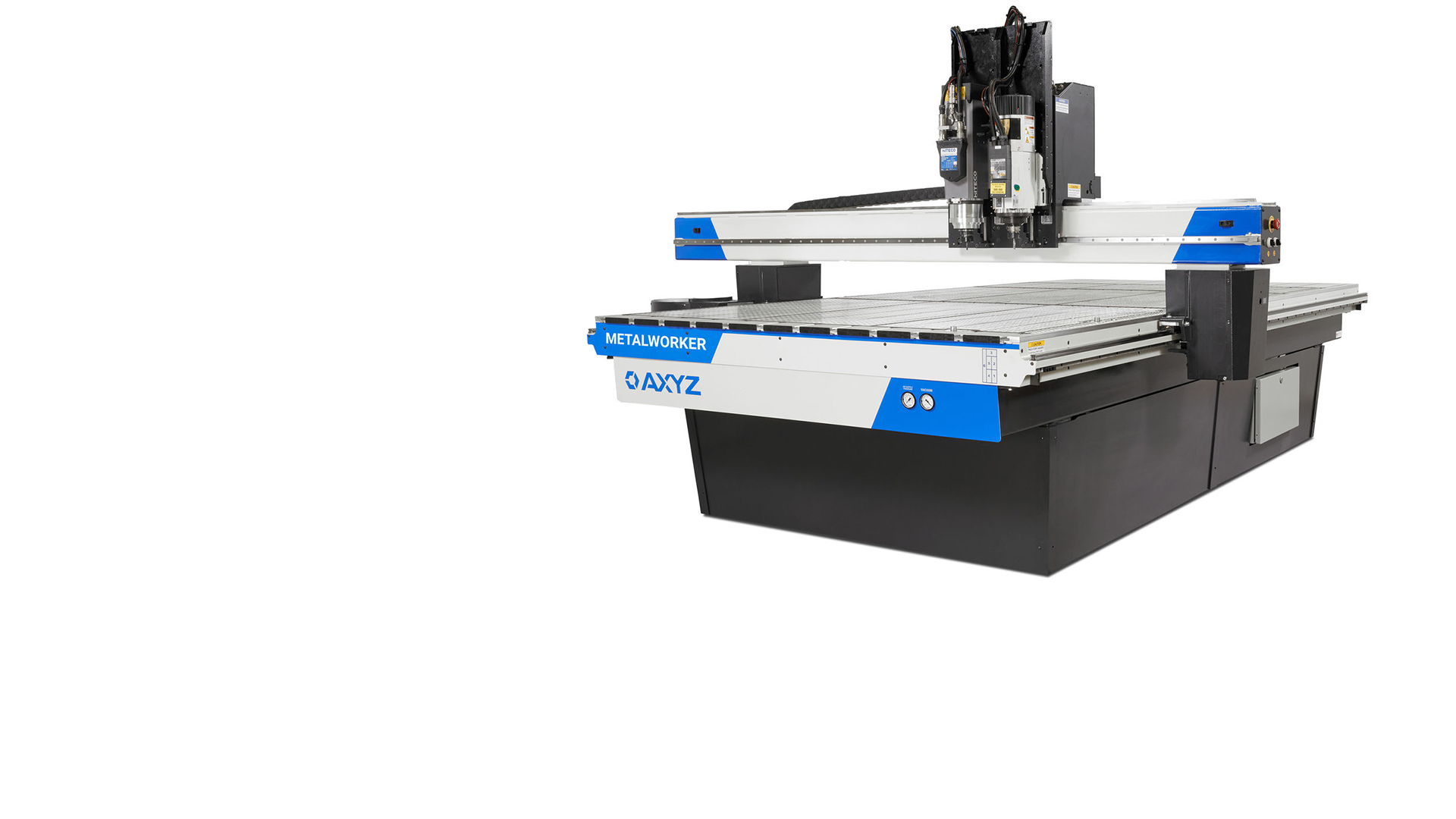

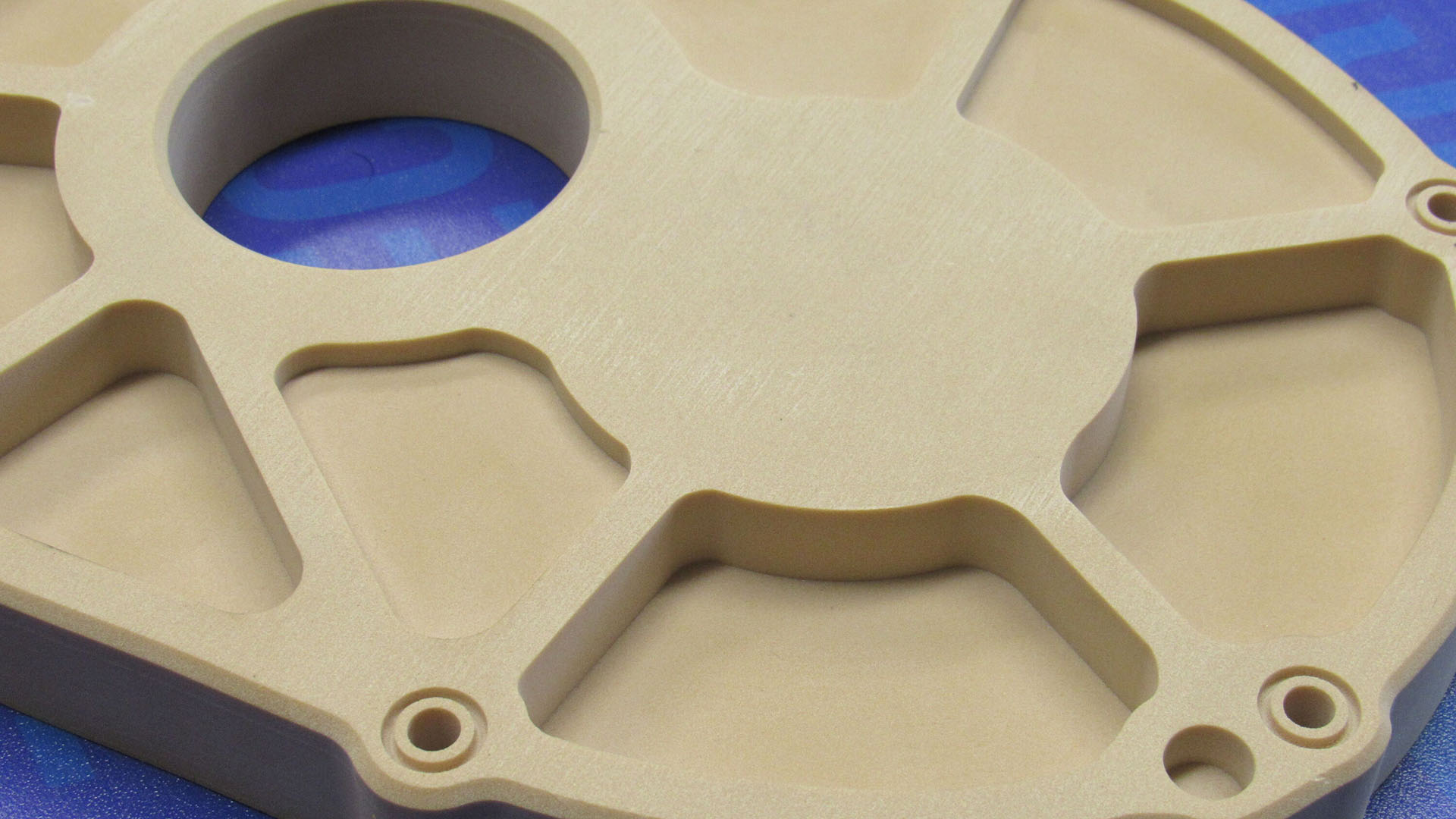

CNC routers are often the most important asset for many companies. When used correctly, they can be incredibly productive and versatile. Over time CNC routers have evolved into sophisticated and complex machinery that are perform a multitude of applications. Technological enhancements such as helical racks, servo motors, robust constructions and multi-functional cutting heads have dramatically increased the number of materials that can be processed using one, standalone machine. Taking the time to understand the full capabilities of a CNC router allows organizations to expand their repertoire of products and achieve a greater return on investment.

Operated correctly, a modern CNC Router will yield excellent results time after time—a process which an experienced operator will make look easy and effortless. However, like all machinery, everything needs to be set just right. If it isn’t there are numerous items that could go wrong and spoil the job, thereby increasing costs and delaying production. CNC machine controllers are a lot smarter than they used to be and are now able to prevent many errors occurring but they are not yet able to catch everything that might go wrong. Typical errors include problems with the CNC program, incorrect machine setup and the use of inappropriate tooling.

CNC routers have been engineered to work to their limits every hour of the day. Like all machinery, routine maintenance is essential to guarantee peak performance and ensure that the equipment is operating as intended. Also, it will also help to reduce the effects of wear and tear and minimize the chance of unforeseen component failures, which can lead to costly production bottlenecks and delays. There are many actions that machine operators can perform on a regular basis that really don’t take much time but that can make a huge difference to machine performance and longevity.

Sign making companies that turn out custom work for clients are now benefitting from the use of programmable CNC routers. This technology is operator-friendly and offers cost-effective ways to maximize productivity, making it ideal even for smaller sign shops, where manpower levels may be an issue.

Published in the October 2016 issue of Sign & Digital Graphics. One of the biggest equipment investments for sign and graphics manufacturers is a CNC router. With practically unlimited capabilities and options, CNC routers and knife hybrids are essential for companies that want to increase and improve their production offerings. To protect the investment in […]

AXYZ, a global leader in CNC router manufacturing, is pleased to announce the opening of its newest office in Somerset, New Jersey. This is AXYZ’s fifth office in the United States, with the other showrooms located in Atlanta, Cincinnati, Los Angeles and Tampa. The expansion of AXYZ into the northeastern United States provides AXYZ with […]

Published in the May 2016 issue of Sign Media Canada. In the sign equipment market, there are CNC vendors and there are CNC system partners. The role of the former is limited to simply supplying equipment and parts, nothing more. The role of the latter, on the other hand, is to work with sign businesses […]