Case Study: Cut to Size Studio Ltd’s Strategic Use of AXYZ Routers to Elevate CNC Machining

Introduction

Founded in 2021 and headquartered in Dotford Bromsgrove, Cut to Size Studio Ltd has quickly established itself as a leader in CNC machining, assembly and finishing services. The company is known for delivering end-to-end solutions that cater to a wide range of industries, from exhibition design to bespoke furniture manufacturing. The company serves a diverse client base, ranging from quick-turnaround exhibition work, full scale rollouts for shop-fitting and office fit-outs, to bespoke, one-off custom pieces. Their services cater to industries such as exhibition design, furniture manufacturing, construction and automotive.

In response to increasing demand for its services, the company expanded its production capacity in 2022 with the acquisition of additional CNC units, enhancing its machining and finishing capabilities. A defining milestone in the company’s growth was the introduction of an AXYZ 8010 Twin Y ATC router in June 2024. This twin-head machine allowed the simultaneous cutting of two large sheets, significantly boosting the company’s output without requiring additional factory space. This strategic investment marked a new era of efficiency and precision for Cut to Size Studio Ltd.

When asked why AXYZ was chosen as the preferred machine supplier James Baker Director and Co-owner said “AXYZ was selected for its combination of accuracy, ease of use and flexibility. The machines allow for the use of multiple tools on the same sheet material, enabling intricate and detailed cuts. Additionally, the ability to machine both faces of components using the same machinery offers versatility and efficiency.”

Challenges

Before adopting AXYZ routers, Cut to Size Studio Ltd faced several operational challenges that impeded its ability to scale and meet the growing expectations of its clients. The traditional CNC machining processes relied heavily on manual labour, which introduced inefficiencies and slowed down production timelines. This created bottlenecks, particularly when managing intricate and detailed cuts that required high levels of precision. The risk of human error in complex cutting processes further contributed to material waste, which added unnecessary costs and reduced overall productivity.

Solutions

To address these challenges, Cut to Size Studio Ltd integrated AXYZ routers into its operations from its inception in 2021. The company selected three key models—the AXYZ 4008 ATC, 6010 ATCand the 8010 Twin Y ATC—each chosen for their exceptional precision, versatility and ease of use. These routers featured automated tool-changing capabilities, enabling the use of multiple cutting tools on a single sheet of material. This multi-tool integration allowed the company to perform intricate and detailed cuts efficiently, significantly reducing the need for manual intervention.

The addition of the AXYZ 8010 Twin Y ATC in 2024 was a game-changer for Cut to Size Studio Ltd. This twin-head machine allowed for the simultaneous processing of two 8×4 or 10×4 sheets, effectively doubling the company’s production capacity. Moreover, the routers’ ability to machine both faces of a component using the same equipment streamlined dual-sided machining processes, enabling the company to meet complex client specifications with ease. The choice of AXYZ machines was also influenced by their user-friendly interfaces and compatibility with a wide range of materials, making them an ideal fit for the company’s diverse project portfolio.

AXYZ was selected for its combination of accuracy, ease of use and flexibility. The machines allow for the use of multiple tools on the same sheet material, enabling intricate and detailed cuts. Additionally, the ability to machine both faces of components using the same machinery offers versatility and efficiency. – James Baker Director and Co-owner

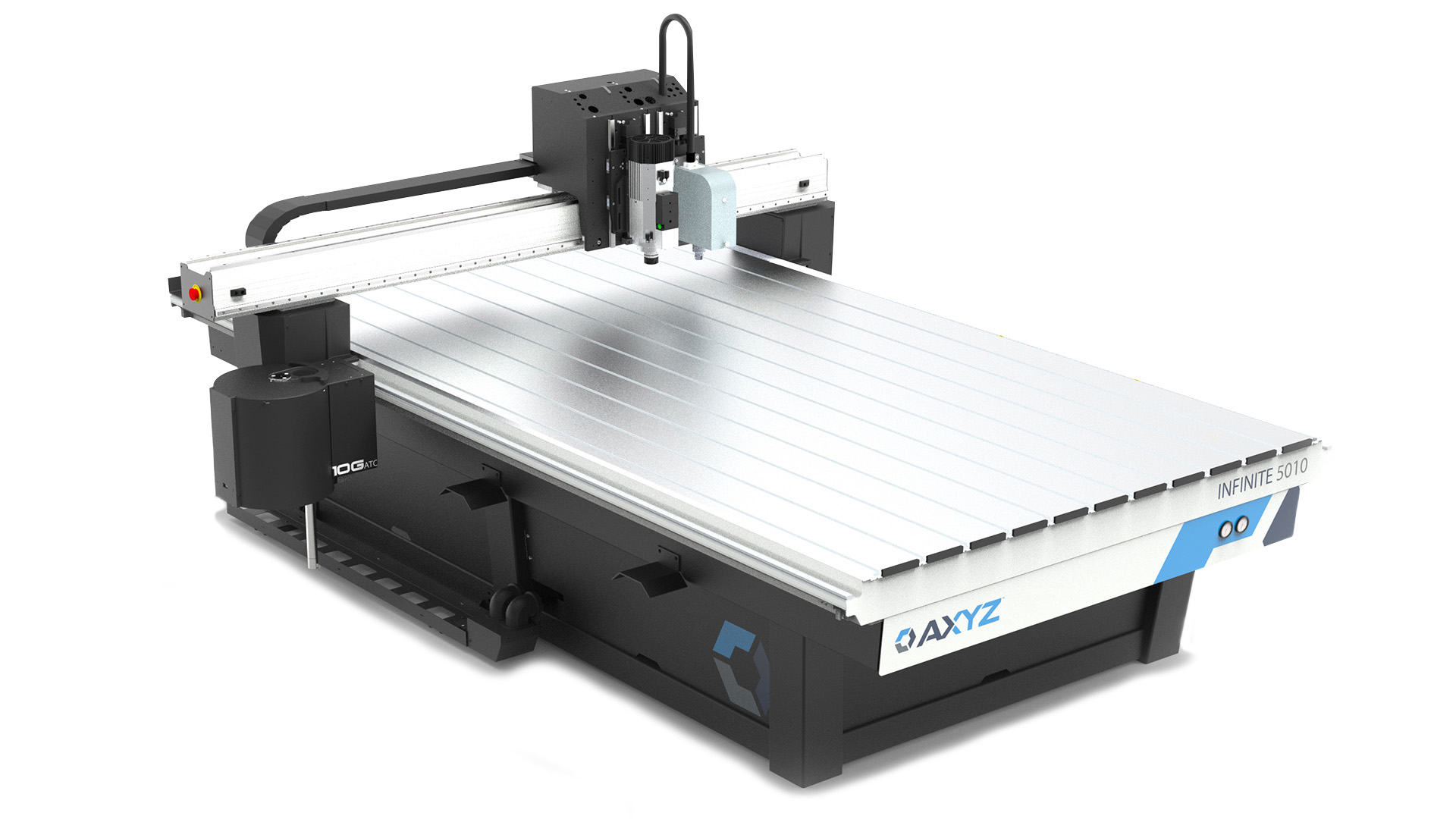

The most recent version of the AXYZ 8010 is the INFINITE router which is a highly configurable CNC machine that is suitable for one-off, small batch production as well as high volume and high productivity applications, including woodworking, plastic fabrication, engineered plastic machining and so much more. For a wide range of routing operations, one can choose from high-speed spindles ranging from 5HP to 15HP. For knife cutting, choose from a tangential knife, which can be used for creasing and folding applications or an oscillating knife which can be used to process soft goods material.

Results

The integration of AXYZ routers brought about a profound transformation in Cut to Size Studio Ltd’s production capabilities. The most significant improvement was the substantial increase in output, driven by the twin-head cutting capabilities of the 8010 Twin Y ATC. By processing two sheets simultaneously, the company was able to double its machining efficiency, allowing it to take on more projects without compromising turnaround times.

Material efficiency also improved due to the precise multi-tool functionality, which enabled more accurate cuts and minimized off-cuts and waste. This not only reduced raw material costs but also enhanced sustainability—a growing priority for many clients. The improved accuracy of the AXYZ machines virtually eliminated human error in component cutting, resulting in higher-quality outputs that consistently met or exceeded client expectations.

The reduced processing time for each component also played a crucial role in shortening project timelines, particularly for industries such as exhibition design and shop fitting, where speed and precision are critical. The company’s reputation for delivering exceptional results within tight deadlines further strengthened its relationships with existing clients and attracted new business opportunities. The enhanced consistency and precision across all jobs ensured that clients received uniform, high-quality components, contributing to increased customer satisfaction and repeat business.

Employee Impact

“The introduction of AXYZ routers reshaped the roles and responsibilities of employees at Cut to Size Studio Ltd in a positive way. Instead of performing repetitive manual labour, employees transitioned to roles that involved overseeing and programming the advanced CNC machinery. This shift not only reduced the physical strain associated with manual work but also opened up new opportunities for skill development” said James.

Comprehensive training programs were implemented to help employees master the use of the AXYZ machines, fostering a culture of continuous learning and technical growth. The ability to work with cutting-edge CNC technology enhanced job satisfaction, as employees took pride in their ability to produce high-precision, complex components using state-of-the-art equipment. The reduction in monotonous tasks also allowed employees to focus on more creative and problem-solving aspects of their work, contributing to a more dynamic and fulfilling work environment.

Workforce and Maintenance

Despite the increased output facilitated by the AXYZ routers, the overall workforce size at Cut to Size Studio Ltd remained stable. However, the skill requirements shifted significantly, with a growing need for technically proficient operators and programmers who could manage and maintain the CNC equipment. The company placed a strong emphasis on upskilling its existing workforce to meet these new demands, ensuring that employees were equipped with the necessary expertise to operate the machinery efficiently.

To maintain optimal performance, Cut to Size Studio Ltd implemented a rigorous maintenance schedule that included regular cleaning, lubrication and calibration of the AXYZ machines. The company performed basic maintenance and repairs in-house, relying on AXYZ’s technical support for more complex issues. This proactive approach to maintenance minimised downtime and ensured that the routers operated at peak efficiency, supporting the company’s commitment to timely project delivery.

Future Plans

Looking to the future, Cut to Size Studio Ltd is committed to further enhancing its production capabilities through additional investments in automation. The company plans to introduce another twin-head AXYZ router to replace one of its smaller units, which will further increase output without requiring additional factory space. This strategic move will enable the company to scale its operations while maintaining its focus on efficiency and precision.

Cut to Size Studio Ltd also aims to continue expanding its expertise in CNC machining by investing in employee training and development, ensuring that its workforce remains at the forefront of technological advancements in the industry. By continually refining its processes and embracing new innovations, the company is well-positioned to meet the evolving needs of its clients and maintain its competitive edge in the market.

Conclusion

The adoption of AXYZ routers has revolutionised Cut to Size Studio Ltd’s CNC machining processes, enabling the company to achieve remarkable gains in productivity, cost-efficiency, and product quality. By leveraging the precision, versatility and efficiency of AXYZ machines, the company has strengthened its reputation as a trusted provider of high-quality, custom-engineered components across multiple industries. With a clear vision for future growth and a commitment to innovation, Cut to Size Studio Ltd is poised to continue its success as a leader in CNC machining, delivering exceptional value to its clients and driving sustainable growth in the years to come.

For more information on Cut to Size Studio Ltd contact

James Baker

Web: www.cuttosize.co

Tel: 01527 352306

For more information on the AXYZ range of routers: www.axyz.com

Tel: 01952 291600

Entrer en contact

Joignez-vous à notre équipe

Votre emploi idéal n’est qu’à un clic. Jetez un œil à nos opportunités actuelles ici.