In the competitive world of architectural cladding fabrication, efficiency, accuracy, and productivity are key factors that determine success. AXYZ’s PANELBuilder CNC Router stands out as the industry’s leading solution, engineered to streamline production while ensuring the highest quality of finished panels. Whether fabricating Aluminum Composite Material (ACM), High-Pressure Laminate (HPL), fiber cement, or solid aluminum, PANELBuilder provides fabricators with a turnkey solution that enhances throughput and maximizes material utilization.

Unparalleled Speed and Accuracy in Cladding Fabrication

Unlike traditional cutting methods, which can be labor-intensive and prone to inconsistencies, AXYZ PANELBuilder CNC routers deliver precision at high speeds. With a solid welded frame, helical rack and pinion drive system, and high-speed spindles, the system enables precise v-grooving, profiling, and part cutting, all with repeatable accuracy.

Additionally, the floating head system ensures consistent v-groove depths, eliminating the common issue of cut variability that can lead to costly rework. This is a crucial advantage over competitors, as maintaining uniform groove depth is essential for the structural integrity and visual appeal of cladding panels.

And now, with the integration of the AXYZ Stud Welder System, aluminum cladding fabrication is taken to a whole new level of efficiency. This state-of-the-art addition automates stud welding for aluminum panels, eliminating manual welding errors and ensuring consistent, high-quality attachment of aluminum studs. The automated bowl feeder streamlines stud placement, while the capacitive discharge power supply and argon gas system guarantee durable, oxidation-free welds—enhancing both structural integrity and production speed.

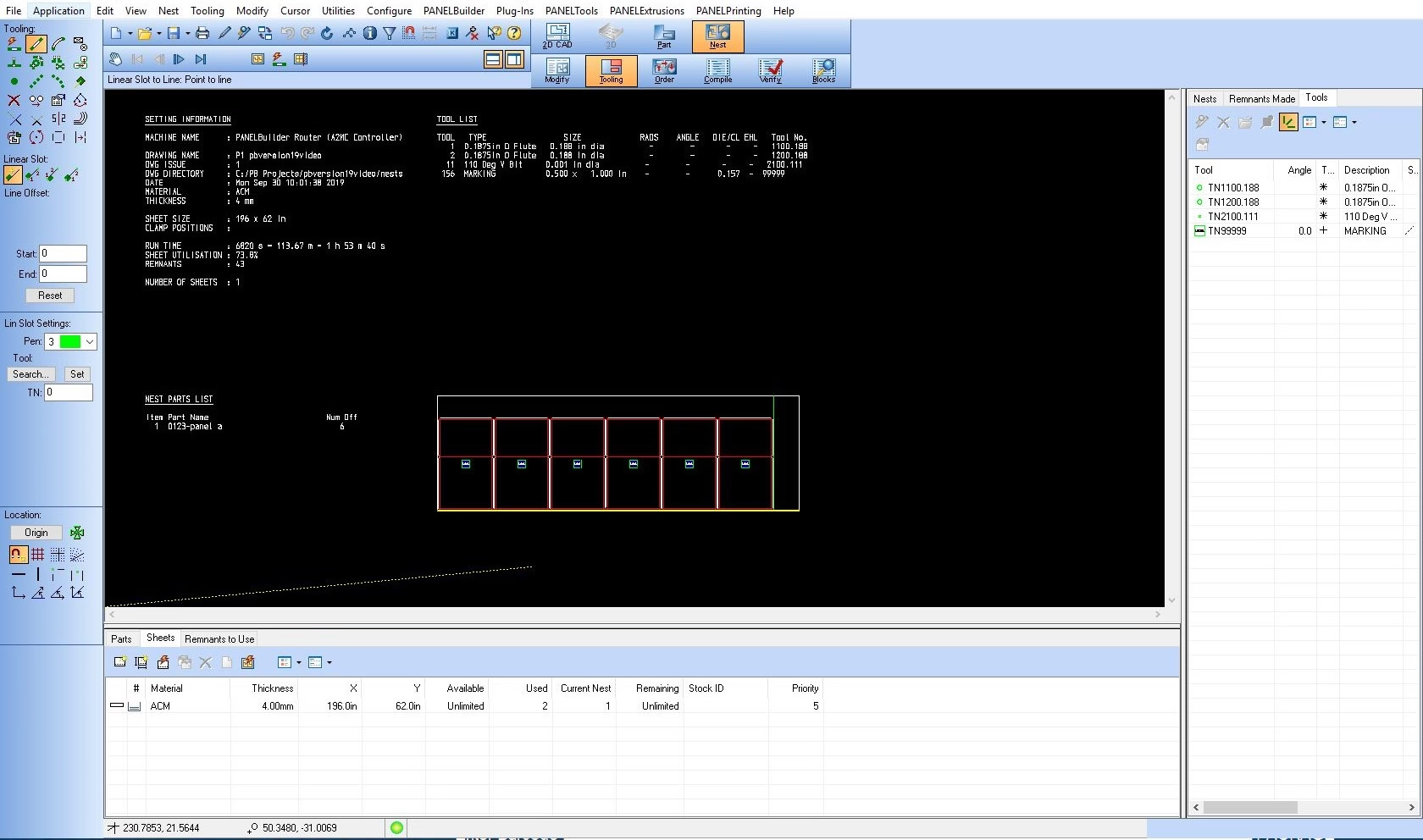

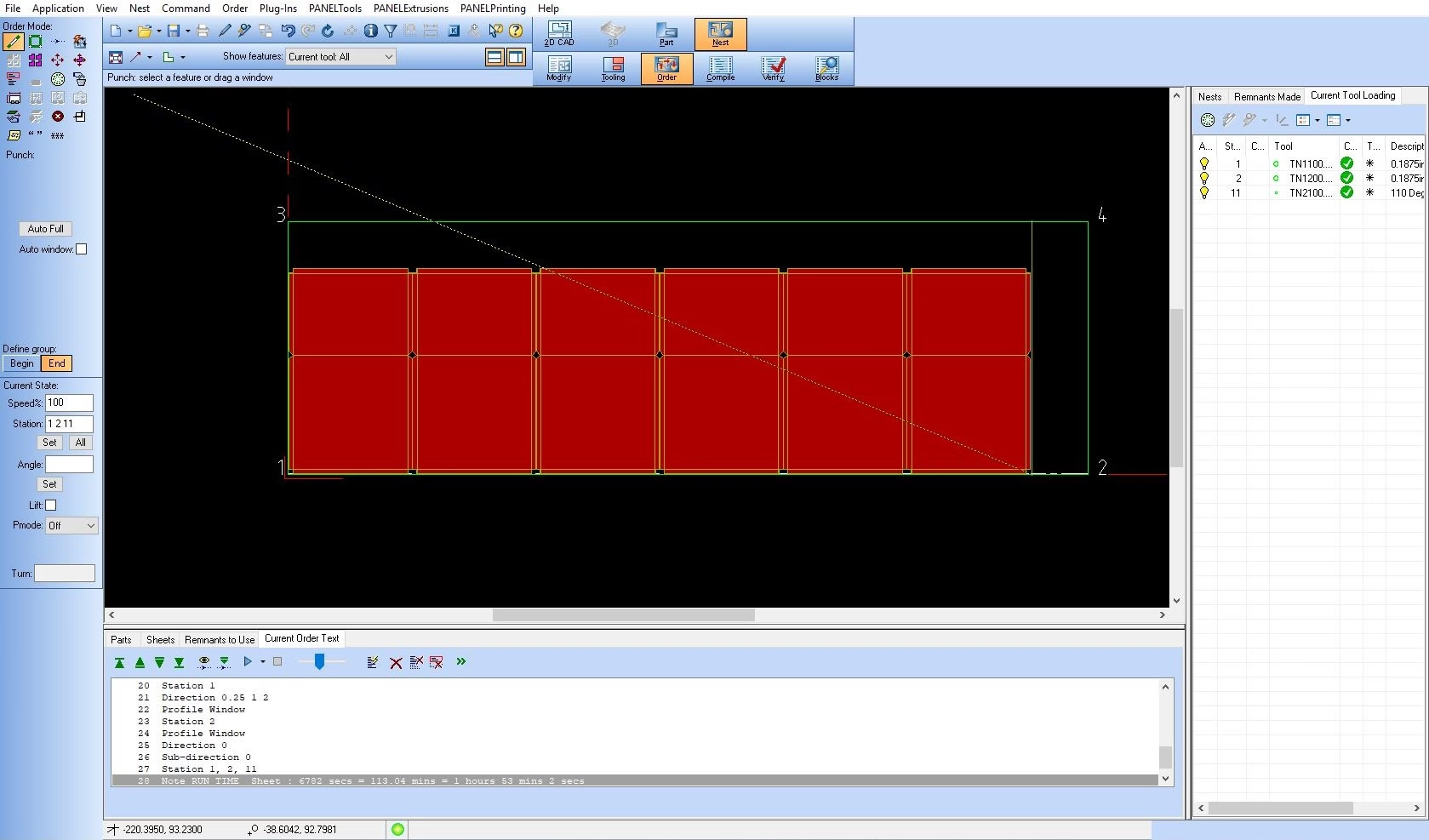

Seamless Workflow with PANELBuilder Software

A significant differentiator for AXYZ’s solution is the PANELBuilder software, which automates key aspects of cladding panel production. This integrated CAD/CAM system enables fabricators to:

- Quickly design panels using parametric tools

- Optimize material usage with powerful nesting algorithms

- Generate toolpaths automatically for efficient CNC routing

- Label and track panels with a barcode-based system

- Reduce production time by managing the entire process in one interface

Fabricators no longer need to rely on multiple software systems—PANELBuilder streamlines the entire workflow from design to fabrication, boosting productivity and reducing errors.

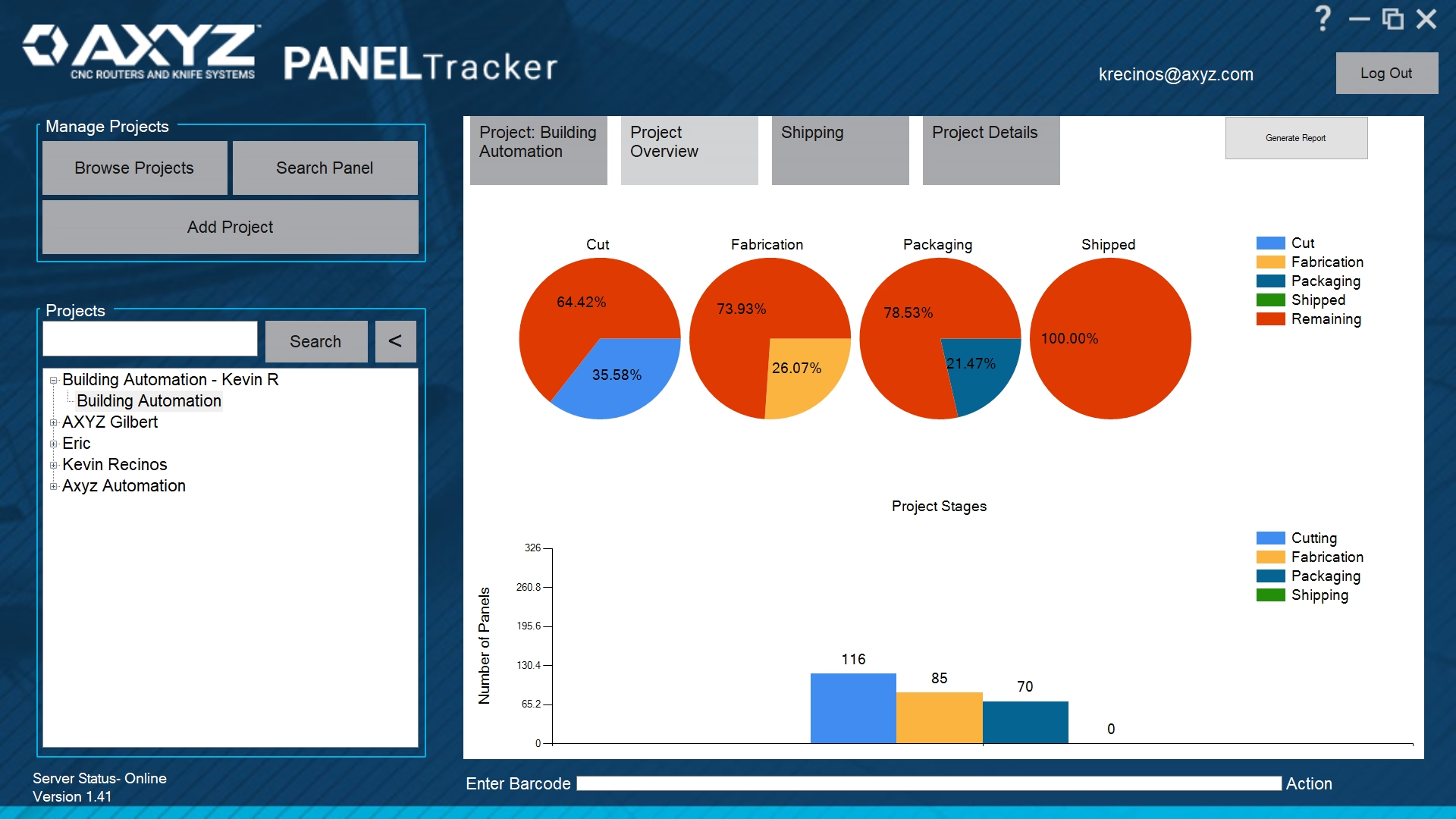

Optimized Production with PANELTracker

For high-volume cladding manufacturers, PANELTracker production tracking software offers an additional advantage. This tool provides real-time insights into production progress, allowing operators to track panels from design to shipment. With built-in quality control features, users can identify defects early, reducing waste and ensuring flawless execution.

- Barcode scanning for panel tracking at every stage

- Re-cut function to manage damaged panels efficiently

- Detailed reporting for production efficiency analysis

This level of control minimizes downtime, improves efficiency, and ensures that fabrication teams stay on track with demanding project timelines.

A Turnkey Solution That Delivers ROI

Purchasing a CNC router is a major investment, and the key to maximizing return is ensuring seamless integration with existing processes. AXYZ PANELBuilder is designed specifically for cladding applications, meaning fabricators can hit the ground running with minimal setup time.

- Industry-Leading Features: Spindle and saw aggregate configurations, pendulum processing, and automatic vacuum control

- High Production Output: Capable of handling large-format materials efficiently

- Low Operating Costs: Advanced nesting capabilities reduce material waste

- Proven Performance: Used by 500+ cladding fabrication companies worldwide

With automated CNC stud welding now part of the solution, fabricators no longer need to rely on separate stud welding setups, cutting down on material handling time and increasing production speeds dramatically.

For businesses looking to expand capacity, reduce labor costs, and improve precision, the AXYZ PANELBuilder CNC solution is the ideal investment.

Conclusion: The AXYZ Solution

With over 30 years of expertise in CNC automation, AXYZ has established itself as the go-to solution provider for architectural cladding fabricators worldwide. The combination of cutting-edge hardware, advanced software, and superior support ensures that businesses remain competitive in an evolving market.

Fabricators looking to increase production speed, minimize waste, and guarantee consistent quality should consider AXYZ PANELBuilder as the industry’s most advanced and trusted CNC solution.

Ready to revolutionize your cladding fabrication process? Contact AXYZ today to learn how PANELBuilder can transform your business.